New bio-based and sustainable raw materials enabling circular value chains of high performance lightweight biocomposites

01 June 2024 – 30 November 2027

Solving the composite challenges in wind energy

In the wind energy sector, composite materials have enabled the construction of lighter and more aerodynamic turbine blades, enhancing performance. However, these materials present significant challenges: their short lifespan, difficult repair process, and lack of recyclability. With 2.5 million tonnes of composite material already in use globally, the sustainability of wind energy faces a critical hurdle. In this context, the EU-funded EOLIAN project introduces smart blades made from infinitely recyclable materials, featuring in-mould electronics for early damage detection. Using vitrimer resins, these blades offer durability, repairability, and circular recyclability, marking a significant shift from single-use engineering resins. The project’s 14m prototype blade will validate these innovations, paving the way for a greener, more efficient wind energy sector.

Objective

Today 2.5 million tonnes of composite material are in use in the wind energy sector globally. Wind turbine blades are made up of composite materials that allow lighter and longer blades with optimised aerodynamic shape, which boost the performance of wind energy. However, current wind blade composites exhibit relatively short life spans, are problematic to repair and are notoriously difficult to recycle. As we continue to build more wind farms these issues pose a major problem to achieving a truly sustainable European wind energy sector.

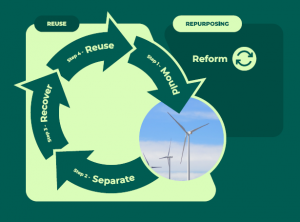

The EOLIAN project will develop an innovative new smart wind turbine blade, manufactured from an infinitely recyclable circular platform chemistry, with in-mould electronics (recyclable sensors and heating actuators) that detect damage early before it becomes a major issue. EOLIAN is the breakthrough that will make obsolete single-use engineering resins in wind blade manufacture. Our unique blade is made using vitrimers, a new class of polymer combining the performance of thermosets with the processability and logistical benefits of thermoplastics. Vitrimer resins enable circularly recyclable composite structures (1), and the option of post-cure processing provides unprecedented manufacturing flexibility (2), but also repairability (3). These three features will provide a truly sustainable and step-change approach in how wind turbine blades are maintained, re-shaped for new applications and/or recycled in a circular economy.

In the project we will validate these performance claims through the manufacture, testing and benchmarking of a smart sensor-assisted vitrimer-based composite 14m prototyped wind blade. Additionally, we will prove circular recyclability through the manufacture of 2nd generation composites with (i) recycled fibers and recycled vitrimer obtained after the chemical recycling by vacuum infusion; (ii) with composite parts produced by SMC (Sheet Mould Compound) following mechanical recycling.

Funded by the European Union under Grant Agreement No 101147532. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union. The European Union can not be held responsible for them.

For more information:

https://cordis.europa.eu/project/id/101147532